Understanding The Basics: Gases & Base Metals

Welding gases can be broadly categorized into inert and active gases. Inert gases, such as argon and helium, serve primarily as shielding agents, protecting the weld pool from atmospheric contaminants like oxygen and nitrogen. On the other hand, active gases like carbon dioxide (CO2) actively participate in the welding process, influencing arc stability and penetration. The welding gas selection process is heavily influenced by the type of base metal being welded.

For instance, argon shielding gas becomes the best choice when welding aluminum (or other non-ferrous metals) due to its excellent arc stability and oxide removal properties. Carbon steel welding, however, often requires the use of gas mixtures such as CO2 welding gas and argon shielding gas for optimal results.

Does Material Thickness Matter In Spring Welding?

Understanding Welding Processes To Choose The Right Gases

For instance, gas metal arc welding (GMAW) commonly uses a blend of CO2 and argon (known as MIG gas mixtures), striking a balance between arc stability and weld penetration. Conversely, gas tungsten arc welding (GTAW) usually utilizes pure argon for its superior shielding properties.

Don’t Forget About The Wind Factor!

Which Welding Gas Should I Choose For My Spring Projects?

For professional welders and metalworking enthusiasts, it might be best to choose specialized gas mixtures tailored to specific applications.

Here’s a brief selection of welding gas for steel and welding gas for aluminum depending on your level of experience:

Beginner Welders

- Welding gas for steel. A great and versatile option is a mix of 75% argon and 25% CO2, thus it provides good arc stability and penetration. It is also great for different thicknesses and welding positions.

- Welding gas for aluminum. As a beginner, you can start with pure argon since it offers great arc stability and helps prevent oxide contamination.

Intermediate Welders

- Welding gas for steel. You may explore a blend of 90% argon and 10% CO2 to enhance your arc stability and weld puddle control. This combination is perfect for welding thick steel materials.

- Welding gas for aluminum. As for welding aluminum, you may opt for a blend of 75% argon and 25% helium, thus the latter helps increase heat input and penetration.

Advanced Welders

- Welding gas for steel. If you’re seeking optimal performance in steel welding, you might want to choose a tri-mix gas blend composed of 90% argon, 7.5% helium, and 2.5% CO2. This combination is ideal for applications that require precision and control.

- Welding gas for aluminum. For advanced aluminum welders, a blend of 98% argon and 2% oxygen provides great arc stability and cleaning action, making the welding process of aluminum easier.

Final Words

In this post, we talked about welding gas selection for spring projects and key considerations to have in mind when moving your work outside. Whether you’re a beginner or advanced welder, the most important thing is to be safe while welding, indoors or outdoors.

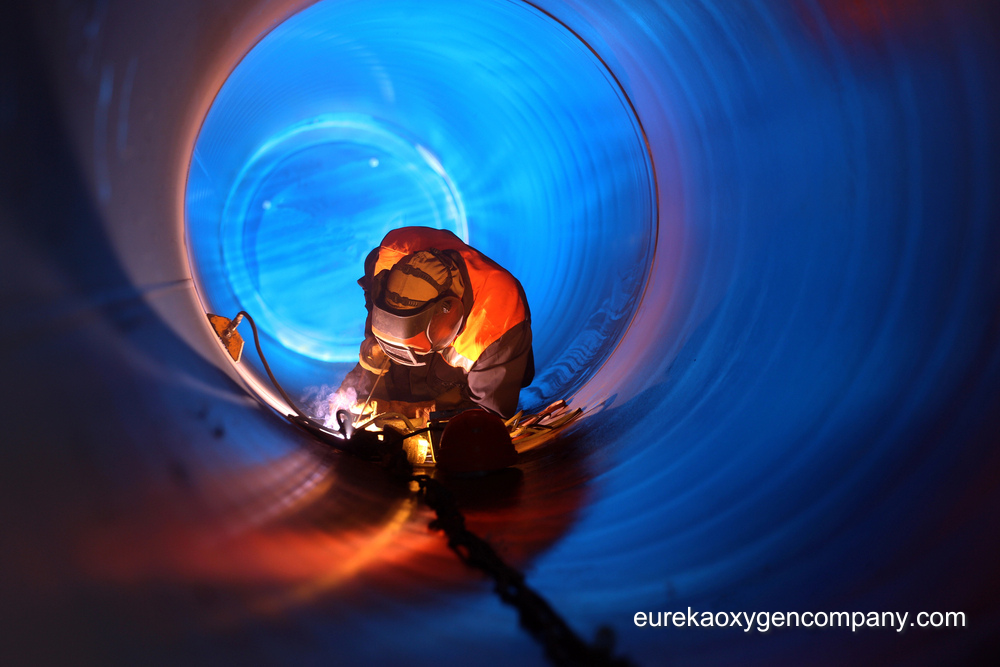

Being mindful of safety recommendations such as wearing appropriate clothing and using tools in great conditions, as well as selecting the right gas mixtures from reliable stores become top priorities.

We’re proud to have a robust selection of welding supplies, including PPE, and welding gases. Our delivery areas include the Counties of Marin, Napa, Sonoma, Lake, Mendocino, Humboldt, Trinity, and Del Norte.