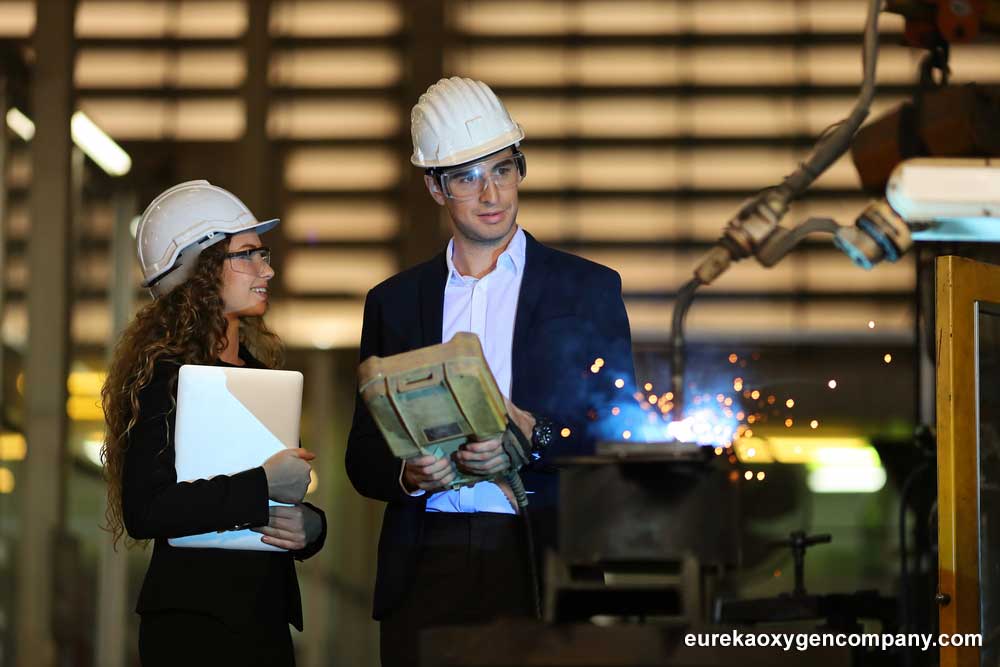

Welding quality management systems

As it was previously mentioned, weld quality isn’t solely about your employees’ work passing inspections. Instead, it goes hand in hand with putting in place effective process control improvements. Welding quality management systems dwell more on the actual quality of the welding process itself rather than simple inspections. Good process controls drive weld quality and include monitoring and controlling process parameters, certifying welding processes, calibrating welding equipment and keeping up-to-date records.

Quality welds & welding inspections

Weld inspections are an integral component of a good quality management system. The actual duty of a welding inspector is to effectively ascertain whether structural welds comply with the acceptance criteria when it comes to applicable codes, specifications, or drawings. Welding inspectors are tasked with the responsibility of evaluating welders’ qualification records, welding processes specifications, weld maps, and so on.

Avenues for continuous welder training

In essence, there is nothing that beats the necessity for welders to gain proficiency in welding skills along with continued training to remain relevant in their profession. When it comes to proficiency, welders can acquire and perfect their skills on the job via hands-on practice. To this end, there are diverse training centers in the country where welding professionals may access quality hands-on and theory instruction. This way, welders get the opportunity to practice and develop indispensable skills and knowledge to ensure they execute quality structural welding in any given situation.